r.e. Series Single Screw Extruders

re125 3/4" Single Screw Extruder

When coupled with the rs5000 Series precision Drives and Torque Rheometers., R.S.I's new line of extruders can be a valuable tool for:

- Measuring Rheological properties

- Processability analysis

- Measuring die swell

R.S.I's family of 3/4" Extruders are available in several L/D Ratios. Made from durable nitrided 416 stainless steel the new r.e. Series of extruders come standard with:

- 2-3 zones of barrel heating and control

- 2-3 zones of air cooling

- 3 1/2-20 threaded ports for use with a pressure transducer, melt transducer or rupture disk at the threaded barrel end

- Industry standard coupling design

- Removeable funnel hopper

- Durable thrust bearing design

- Feed throat cooling connection

- Removeable heater wires for easy storage

- Rupture disk protection at end of barrel

- Universal threaded barrel end design for easy die installation and compatability

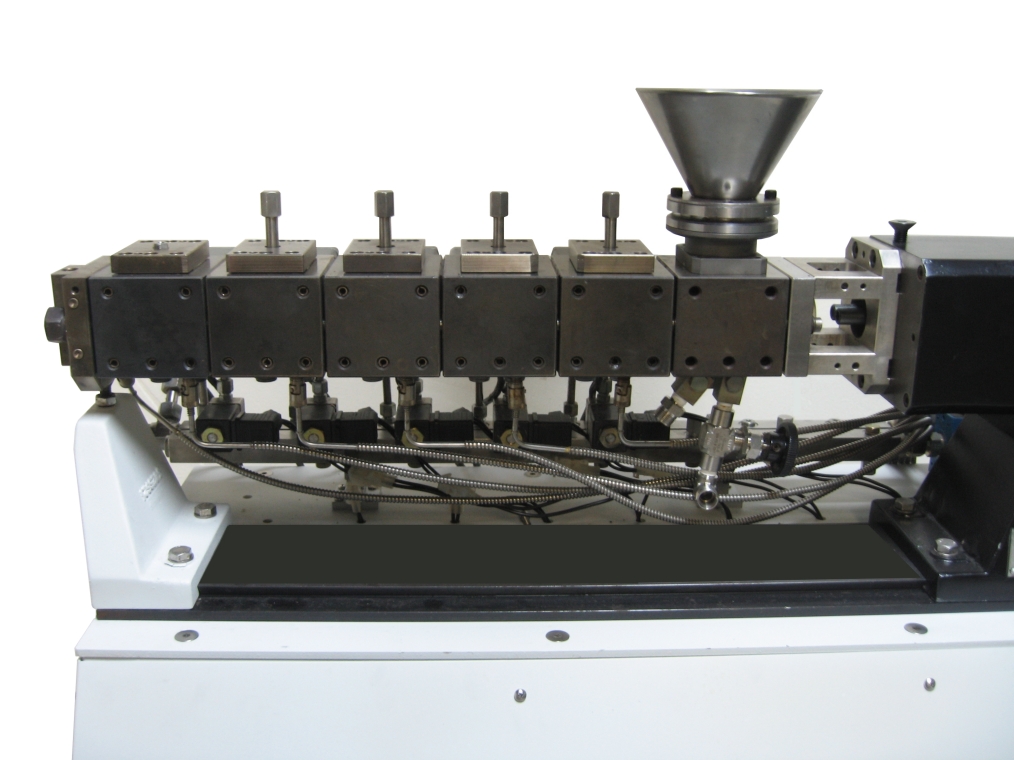

18mm Twin Screw Extruder

The 18mm Twin Screw Extruder available from RSI is specially designed as an attachment for the rs5000-S5 Torque Rheometer and is ideal for laboratory compounding of thermoplastic materials offering a flexible design for new products. The 18mm diameter screws have a 3.5mm flight depth and are assembled of high torque splined shafts. This allows for the screw profile to be altered at any time. The segmented barrel allows the user to change L/D ratio as desired. The material is metered into the twin screw via a volumetric, loss and weight or liquid feeder system. A full line of downstream ancillary equipment is available to provide the customer with a turnkey universal compounding extrusion line.

SPECIAL FEATURES

- Co-rotation with up to 1500 RPM screw speed

- Segmented barrels and screws

- Quick change, flangeless barrels with tie rod assembly

- Electric cartridge heaters for barrel heating

- Internal bored for barrel air cooling

- Mounted on mobile cart for easy connection/disconnection and storage

- Results scalable to production class machinery

OPTIONS

- Various L/D ratios up to 40:1

- Side stuffers available for downstream feeding

- Liquid injection ports

- Solids and liquid feeder systems

- Compatible with all RSI dies and downstream systems